- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Multi-index evaluation of the effect of different drying methods on the quality of Beiqing Longyi

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Multi-index evaluation of the effect of different drying methods on the quality of Beiqing Longyi

2019-01-02 11:38:41Objective: To study the effect of different drying methods on the quality of Beiqing Longyi, and to optimize the best drying method of Beiqing Longyi.

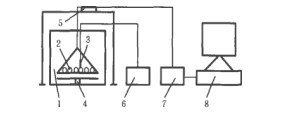

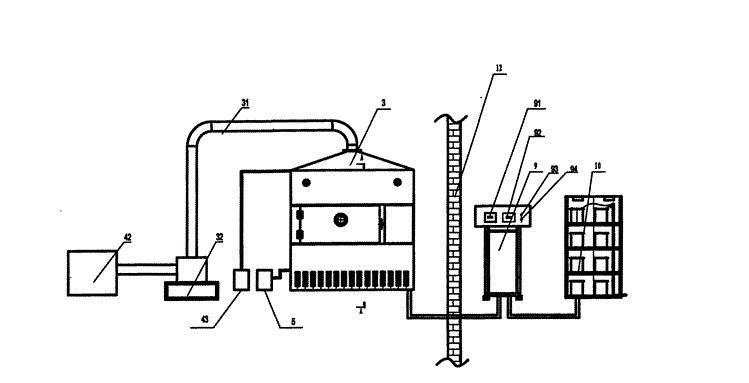

METHODS: After five drying methods (shade drying, sun drying, drying, microwave drying equipment, freeze drying) and different drying temperatures (40, 50, 60 C) under different drying methods, Beiqinglongyi was treated with drying time, rehydration rate, water content, alcohol extract content, effective components of walnut quinone and walnut ketone and their methanol extracts on human gastric adenocarcinoma BGC 823 cells and human lung cancer A54 cells. The effect of different drying methods on the quality of Beiqinglongyi was compared and analyzed.

Result: Among the five drying methods, microwave drying time was the shortest and shade drying time was the longest; freeze-drying sample had the largest moisture content and microwave drying sample had the smallest moisture content; the content of alcohol extract had little difference; the content of walnut quinone was the highest in freeze-drying sample and the lowest in microwave drying sample; the content of walnut ketone was the highest in drying sample at 40 C and the lowest in freeze-drying sample in vitro. Tumor test showed that freeze-drying > drying at 40 C > shade-drying were the drying methods according to the growth inhibition rate of the two kinds of cells, and the inhibition rate decreased with the increase of drying temperature.

CONCLUSION: Different drying methods have obvious effects on the quality of Beiqing Longyi. From Cost to Effective Component

The content, antineoplastic activity and practicability of Beiqinglongyi were comprehensively analyzed. It was suggested that the drying method of Beiqinglongyi should be at 40 C.

Key words: Beiqing Longyi microwave drying; drying method; drying; walnut quinone; walnut ketone; in vitro antitumor activity

Beiqinglongyi is the immature exocarp of Juglans mandshurica, which is mainly produced in three northeastern provinces. Heilongjiang Province has the largest resource reserves. It is included in the 2001 edition of Heilongjiang Province Chinese Medicine Standard.

Classics record its bitterness, bitterness, astringency and tranquility, which has the effect of clearing away heat and detoxification, dispelling wind and treating tinea, and relieving pain and treating dysentery. Modern pharmacological studies have shown that Beiqinglongyi has obvious anti-tumor activity. It contains naphthoquinone and its glycosides, diarylheptane, flavonoids, terpenoids, organic acids and other chemical components. Juglone is a clear anti-tumor active ingredient in Beiqinglongyi.

The traditional drying method of Beiqinglong clothes after harvesting is to dry in shade or to dry in semi-dry place with ventilation. This drying method has long drying cycle, low drying efficiency, and there are many problems such as perishable and mildew of medicinal materials, microbial pollution, loss of effective ingredients and so on. With the development of modern drying technology, it is necessary to apply more efficient drying technology to the production and processing of traditional Chinese medicine.

Therefore, modern drying technologies such as microwave drying and freeze drying were applied to the drying of Beiqinglong clothes. The effects of different drying methods on the quality of Beiqinglong clothes were compared and analyzed in order to improve the quality and drying efficiency of medicinal materials and provide a scientific basis for the drying process of Beiqinglong clothes.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply