- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Preparation of High Quality Pure Chicken Powder by Microwave Drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Preparation of High Quality Pure Chicken Powder by Microwave Drying

2019-01-02 13:47:22

Absrtact: The technology of producing pure chicken powder by microwave drying was studied and analyzed. The optimum technological conditions for producing pure chicken meal were determined by single factor experiment and orthogonal experiment as follows: adding 0.6% bio-enzymes, extracting temperature 120 C, extracting time 2 h, feed-water ratio 1:1, homogenization 3 times.

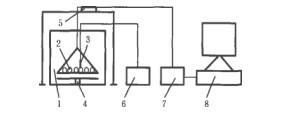

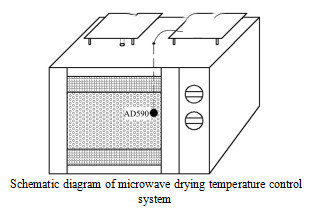

The microwave drying equipment opens 36 microwave sources, the material thickness is controlled at 2-3 mm, and the feed speed is adjusted to 2 cm/s. The pure chicken flour chicken produced is pure in taste, mellow in taste, rich in head fragrance, high in protein content, low in water content, long in shelf life, and can adapt to the actual industrial production.

Key words: microwave drying of pure chicken powder; enzymatic hydrolysis; aqueous phase extraction; microwave; homogenization

China is a major poultry farming country in the world. Its main products are poultry meat and products, down and feather products, and egg products. The utilization rate of by-products such as poultry skeleton in deep processing is very low. Pure chicken meal is prepared with chicken skeleton as the main raw material. Vigorously developing pure chicken meal products can not only solve the problem of low utilization rate of chicken skeleton, but also further promote the development of agriculture and industry mainly based on breeding.

Pure chicken powder products are widely used in instant noodle condiments, puffed foods, meat and aquatic products and other food processing fields. In actual production, the use of pure chicken powder in chicken essence (powder) ranges from 3.5% to 6.5%. The usage of instant noodle condiments ranges from 8% to 18%. The amount of pure chicken powder used in extruded foodstuffs is 3.5%-7.7%. The amount of pure chicken powder added in chicken soup powder is 5%-8%.

These condiments play an irreplaceable role in daily life. With the improvement of people's requirements for quality of life, people's demand for pure natural and healthy condiments is also higher. Pure chicken powder is such a safe, nutritious and convenient product. It is not difficult to see that the market prospect of pure chicken powder is very broad, and it is of great significance to improve the quality of this product.

Most of the chicken sold in the market is produced by spray drying process. The pure chicken powder produced by this process has high water content, which leads to the long shelf life of natural products. In addition, the yield of pure chicken meal produced by this process is low and the impurities are high.

Microwave drying process is the same direction of heat and mass transfer. The internal temperature of materials causes the internal and external moisture to spread evenly. Therefore, the drying speed is fast, and it is more suitable for the drying of spherical particulate matter. In order to obtain a kind of pure chicken powder with high purity, high stability and high quality, the microwave drying technology and principle were systematically studied in this work.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply