- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of microwave drying on quality and volatile substances of wild shepherd's Purse

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of microwave drying on quality and volatile substances of wild shepherd's Purse

2019-01-03 10:11:20ABSTRACT: In this paper, the effects of different microwave drying processes on the quality and volatile substances of wild shepherd's purse were studied.

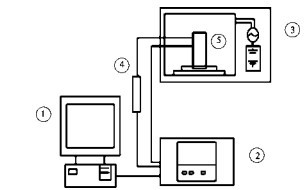

The volatile substances of wild shepherd's purse were analyzed by headspace solid phase microextraction (HSSPME) combined with gas chromatography-mass spectrometry (GC-MS) using 120 W, 240 W, 360 W, 480 W, 600 W and 700 W microwave power.

The results showed that microwave drying equipment resulted in a significant decrease in the contents of characteristic alcohols such as folic alcohol, trans-2-hexene-1-alcohol, 2,6-dimethylcyclohexanol and so on. The types and contents of aldehydes decreased slightly, but the contents of isovaleraldehyde, (E) -2-pentenal, n-octanaldehyde and phenylacetaldehyde increased, and the contents of isovalerate nitrite and ethyl 2-methyl-valerate increased. Acidifiers such as 3-methyl butyric acid, 2-methyl butyric acid, hexanoic acid and octanoic acid disappeared, while hydrocarbons such as styrene and cyclotetradecane disappeared.

The quality test showed that the sensory quality of dried buckwheat products was better under 480W drying condition. The retention rates of chlorophyll and VC were 67.14% and 71.20% respectively. The most volatile aromatic compounds were volatile aromatic compounds, and the retention rates of volatile substances were 93.68%. The retention rates of alcohols and aldehydes were higher, and that of beta-ionone was 84.21%.

Key words: microwave drying shepherd's purse; volatile substances; gas chromatography-mass spectrometry (GC-MS); quality

In recent years, with the improvement of people's consumption level and the change of dietary concept, more and more wild vegetables are moving from mountain to dining table, which plays a very important role in enriching people's vegetable basket. At the same time, many wild vegetables have certain pharmacodynamic functions, which are more and more popular with consumers. Shepherd's purse, a cruciferous plant, is an edible wild vegetable suitable for all ages.

Wild shepherd's purse leaves are scattered and grow on the ground with gray-green color. The fragrance and sweetness, due to the rich glutamic acid and other amino acids, tastes delicious, known as the "top quality of wild vegetables". As far as aroma is concerned, shepherd's purse mostly presents the unique fragrance of grass leaves and fruits and vegetables.

As a special wild vegetable, shepherd's purse can alleviate the shortage of green vegetable in winter, but its edible value and economic benefit can not be brought into full play due to the obvious seasonal restriction of growth and short picking and storage periods. Using appropriate drying technology to process shepherd's purse into dry products can not only meet different consumption needs, but also effectively prolong the supply time of shepherd's purse products.

At present, the most commonly used method of vegetable drying is hot air drying, but the hot air drying time is long, the drying temperature is high, and the drying process destroys the structure of the product. After drying, the quality of the product decreases seriously and the nutrition loss is great. Although freeze-drying can preserve the natural quality and nutritional value of products to a large extent, its application is limited due to the long drying time, expensive equipment and high production cost. Because of its unique heating characteristics, microwave drying directly penetrates into the interior of the material during drying, which makes the internal and external moisture vaporize at the same time, and has a strong ability to remove moisture from the material, thus making up for the shortcomings of traditional drying methods.

Wild shepherd's purse has its unique aroma, and the influence of drying technology on aroma substances is also the focus of investigation. The author established a method to detect the volatile substances in wild shepherd's purse by solid phase microextraction combined with gas chromatography-mass spectrometry (GC-MS) in the early stage, and identified the main volatile substances in wild shepherd's purse, which laid a foundation for this study. In this paper, the effects of different microwave drying power on the quality and volatile substances of wild shepherd's purse were studied to provide theoretical basis for searching for the best drying technology of wild shepherd's purse.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply