- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> The relationship between microwave technology and wood drying development

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

The relationship between microwave technology and wood drying development

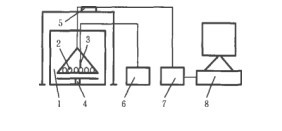

2019-01-03 10:48:55Absrtact: Microwave technology, with its unique heating mechanism and characteristics, provides a new way for rapid and efficient wood drying. In this paper, some important advances in wood microwave drying technology at home and abroad in recent years are reviewed, mainly focusing on the optimization of basic drying parameters such as microwave power, moisture content and temperature, and the application of advanced detection technology such as infrared camera technology.

At the same time, the lack of systematic research on the basic theory of wood microwave drying equipment, drying technology, wood structure characteristics and microwave heating inhomogeneity was pointed out. It is suggested that the basic theory research should be strengthened in the future and the modern measurement and control technology should be used in the systematic research.

Key words: wood microwave drying; microwave technology; research; progress

In recent years, the demand for wood is increasing, but the conventional wood drying can not meet the market demand because of the shortcomings of long drying time, energy consumption and serious pollution. Therefore, people began to seek and study new wood drying technology.

Microwave technology originated in the 1930s and became a hotspot in the world because of the discovery of its thermal effect. Then in the 1960s and 1970s, many countries began to apply this technology to wood drying, and finally, with its unique heating mechanism and characteristics, it provided a new way for wood drying quickly and efficiently. In recent years, wood microwave drying technology has made some important progress in basic drying characteristics, drying technology and detection technology, but there are still many outstanding problems to be solved in the process of application research.

With the deepening of research at home and abroad, wood microwave drying technology has made certain progress. Future research directions include the following aspects:

1) Deeply study the theory of heat and mass transfer of wood, establish an accurate mathematical model, and provide a theoretical basis for microwave drying technology.

2) Develop on-line measuring instrument to detect the temperature and moisture content of wood in drying process in real time, so as to control the drying process.

3) The dielectric properties and drying quality of wood commonly used in industry were studied in order to formulate a reasonable drying process.

4) Designing and manufacturing microwave drying equipment suitable for industrial production to promote the application of this technology.

5) Combine microwave drying with other drying methods organically to give full play to their respective advantages.

With the increasing tension of wood resources and the increasing demand for wood, wood microwave drying, as one of the important ways to ensure wood utilization and meet market demand, is of great significance.

However, microwave drying of wood consumes a large amount of electricity and has a high investment in equipment. It is not suitable for mass drying of wet wood, but suitable for secondary drying of semi-dry wood with a small amount of drying batches to supplement the shortcomings of conventional drying. We must make full use of our strengths and avoid our weaknesses and use microwave drying skillfully. We believe that microwave technology will have a wider application prospect in wood industry.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply