- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of different drying methods on tea flower quality

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of different drying methods on tea flower quality

2019-01-04 13:15:52ABSTRACT: The biochemical constituents of tea flowers and fresh tea leaves are basically the same. They are rich in tea polyphenols, tea polysaccharides, free amino acids, superoxide dismutase (SOD) and caffeine, and have very high value for development and utilization. The effects of vacuum freeze drying, constant temperature oven drying and microwave drying equipment on the quality of dried tea flower were studied.

(1) Vacuum freeze-dried dried tea tree flowers better preserve the shape, aroma and color of tea tree flowers; dried tea tree flowers are relatively natural in shape, darker in color and sweeter in fragrance; microwave dried tea tree flowers are shrunken in shape, dark in color, long in sweet fragrance, and have the fragrance of meritorious service.

(2) The water extract content, soluble sugar, tea polysaccharide, tea polyphenols, tea saponin and free amino acid content of dried flower of tea tree dried by vacuum freeze-drying were the highest; the water extract content, tea polysaccharide and tea polyphenol content of dried flower of tea tree dried by microwave drying were higher than that of dried flower of tea tree, and the soluble sugar content was lower than that of dried flower of tea tree; the caffeine and total flavonoids content of dried flower of tea tree dried by three processing methods were higher than that of dried flower There was no significant difference in quantity.

Key words: tea flower microwave drying; vacuum freeze drying; drying; quality; processing methods

Tea appeared and was drunk thousands of years ago. "Tea is a drink, originated from Shennong" can prove the history of tea drinking. In the past, people focused on the buds and leaves of tea plants, ignoring the use of tea flowers. In recent years, tea blossom has attracted much attention, and its research reports have increased, but it is still in the research stage, with little practical application.

Tea tree flower and tea fresh leaves have the same biochemical composition. They are rich in tea polyphenols, tea polysaccharides, free amino acids, superoxide dismutase (SOD) and caffeine, and the content of Theanine and other active ingredients is high. Therefore, tea tree flower has great application value and broad development prospects as tea. Tea flower has high water content. In order to ensure its quality, it is necessary to dry tea flower. Dry flower processing is the basis of its further processing and utilization.

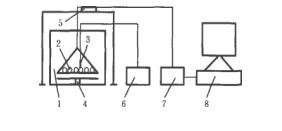

In this paper, three varieties of tea tree flowers, Shuchazao, Nongkangzao and Wuniuzao, were selected as raw materials. After spreading and microwave sterilization, three drying methods, vacuum freeze-drying, constant temperature oven drying and microwave drying, were used to process dried tea flower. The quality of dried tea flower was studied through sensory evaluation and biochemical analysis.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply