- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Optimum selection of different drying methods for extract of Qiwei Shuanghua Chaihu Capsule

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Optimum selection of different drying methods for extract of Qiwei Shuanghua Chaihu Capsule

2019-01-04 16:51:47

ABSTRACT: OBJECTIVE To optimize the drying process of Qiwei Shuanghua Chaihu capsule extract. Methods taking dry paste characteristics, yield, hygroscopicity and chlorogenic acid transfer rate as evaluation indexes, three drying methods, vacuum drying, microwave drying equipment and spray drying, were investigated.

Results the transfer rates of chlorogenic acid in dry paste prepared by vacuum drying, microwave drying and spray drying were 82.5%, 89.6% and 92.3% respectively, and the dry paste quality was 17.66mg. G - 1.

19.89 mg.g-1 and 20.71 mg.g-1 respectively.

Conclusion spray drying time is the shortest, the appearance characteristics of the obtained materials are the best, and the transfer rate of the index components is the highest. It is the best drying method for the seven flavored double flower Bupleurum extract.

Key words: seven kinds of double flower Bupleurum capsule; chlorogenic acid; vacuum drying; microwave drying; spray drying; microwave drying of Chinese medicine.

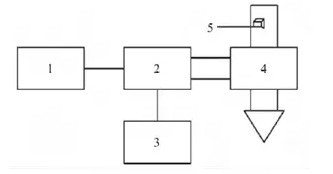

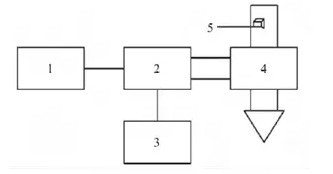

At present, the most commonly used drying processes in the pharmaceutical industry include vacuum drying, freeze-drying, spray drying and microwave drying. Their principles are heat conduction, thermal convection, dielectric heating and so on. Due to the different drying methods and principles, the content of index components and physical properties of drying products are different, and more and more attention has been paid to the study of traditional Chinese medicine technology.

Qiwei Shuanghua Chaihu Capsule, which belongs to six kinds of new Chinese medicines, is composed of honeysuckle, Bupleurum chinense, Forsythia suspensa, Scutellaria baicalensis, Pinellia ternata, Panax quinquefolium, Mianma Guanzhong. It has the functions of detoxifying pathogens, clearing lung and releasing heat. It is mainly used to treat viral upper respiratory tract infections (belongs to wind-heat syndrome). Honeysuckle in the prescription is the monarch medicine, in which chlorogenic acid is the main index component in the extract of Seven-flavor Shuanghua Bupleurum.

Chlorogenic acid is an ester formed by caffeic acid and quinic acid. There are three unstable parts in the molecular structure: ester bond, unsaturated double bond and polyphenol. It has been reported that chlorogenic acid is unstable and easy to decompose after being exposed to light and heated. Therefore, in order to ensure the stability and reliability of the production process of Qiwei Shuanghua Bupleurum Capsule and effectively control the quality of the product, the drying method of Qiwei Shuanghua Bupleurum Capsule Extract was investigated.

Considering the follow-up preparation technology, besides investigating the transfer rate of chlorogenic acid and the yield rate of Qiwei Shuanghua Bupleurum Dry Ointment, this experiment also made a comparative study on its appearance and hygroscopicity, so as to grasp the characteristics of different drying methods of traditional Chinese medicine extracts and guide the preparation process.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply