- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of different drying methods on banana quality

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of different drying methods on banana quality

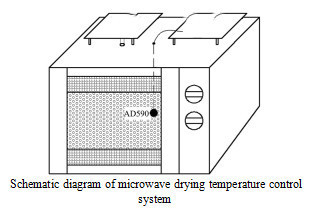

2019-01-08 09:53:18ABSTRACT: In order to compare the effects of six different drying methods on nutrient composition, microstructure, sensory quality, flavor composition and production cycle of banana drying products, such as ordinary hot air drying, vacuum freeze drying, traditional frying drying, vacuum drying, microwave drying equipment and variable temperature and pressure differential expansion drying.

The comprehensive evaluation results of drying methods are as follows: vacuum freeze-drying > variable temperature and pressure differential expansion drying > traditional fried drying > vacuum drying > vacuum microwave drying > ordinary hot air drying. However, vacuum freeze-drying has the advantages of large investment and long production cycle, and variable temperature and pressure expansion drying has the largest micro-cell structure gap, which gives the product porous structure.

Key words: banana microwave drying; drying method; nutrient components; microstructure; flavor components; coefficient of variation

Banana is rich in nutrition, protein, carbohydrates, dietary fiber, trace elements, vitamins and bioactive ingredients. It has the physiological effects of moistening intestines and relieving constipation, improving sleep and beauty. There are 130 countries and regions planting and cultivating bananas all over the world. China is rich in banana resources and ranks third in the world in total output.

However, the phenomenon of banana unsalability in recent years has caused huge economic losses, seriously affecting the enthusiasm of banana farmers. It is urgent to research and develop new technology and technology of banana processing and preservation, so as to prolong the storage period of bananas. Drying preservation is one of the best ways of banana preservation. It is particularly urgent to find a suitable drying technology for banana industrialization development.

Drying technology is an important unit operation technology in modern food engineering, which is widely used in the processing of various kinds of food. The principle of drying technology processing and preservation is to reduce water content and water activity to achieve bacteriostasis and inactivation of enzyme activity, so as to better ensure product quality and prolong shelf life.

At present, the main methods of banana drying are general hot air drying, traditional fried drying, vacuum freeze drying, vacuum drying, vacuum microwave drying, temperature-varying pressure differential expansion drying.

The effects of six different drying methods on sensory quality, nutrient composition, microstructure and flavor substances of banana dried products were studied in this experiment. The aim was to provide technical support and theoretical basis for the selection and application of processing methods of banana dried products by investigating the effects of six different drying methods: ordinary hot air drying, vacuum freeze drying, traditional frying drying, vacuum drying, vacuum microwave drying and variable temperature and pressure expansion drying. According to.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply