- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on the effect of drying method on aging characteristics of instant acorn powder

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on the effect of drying method on aging characteristics of instant acorn powder

2019-01-09 10:11:44ABSTRACT: Controlling the aging degree of powder skin is the key to produce high quality and convenient powder skin. In this paper, the influence of different drying methods on aging characteristics of instant acorn powder was studied by infrared analyzer, X-ray diffraction and fast viscosity analyzer, and the microstructure of powder was studied and evaluated by scanning electron microscopy.

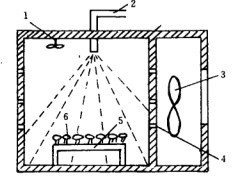

The results showed that compared with hot air drying, the iodine chroma of powder skin increased significantly (p < 0.05), the infrared absorbance and retrogradation value decreased significantly (p < 0.05), and the crystallinity also decreased. The powder skin has looser microstructure and larger voids. The aging degree of powder skin in microwave drying equipment is low.

Key words: Acorn powder microwave drying, drying method, aging characteristics, microstructure

Acorns are commonly known as oak fruits of Fagaceae plants, but do not include artificially cultivated chestnuts. Acorn resources are abundant in China. There are 7 genera (Cyclobalanopsis, Cyclobalanopsis, Castanopsis, Quercus, Quercus, Quercus and Chestnut) 301 species, which are widely distributed in temperate and subtropical zones. The planting area of oak is as high as 1.33 x 107-1.67 x 107 hm2, and the annual output of acorn is as high as 6-7 million tons. In this paper, acorns of Quercus glauca, which are common in southwest China, were used as experimental materials.

Quercus glauca is an evergreen tree belonging to the genus Cyclobalanopsis of Fagaceae, also known as Quercus ferruginosa, Castanopsis fargesii and Paulownia tenuifolia. It has abundant nutritional components. Besides starch, protein, oil and other basic components, it also contains tannins, flavonoids and other functional components. It has high medicinal value and is widely used in antioxidant, free radical scavenging, anti-cancer and so on. The traditional food processed by acorn is mainly fresh and wet products with local characteristics, such as acorn powder, cakes, tofu and acorn paste, which have short shelf life and are not convenient for long-distance transportation. Therefore, it is very important to use acorn to produce convenient acorn powder.

The main evaluation index of convenient rubber powder is rehydration. The results show that the rehydration of instant food is closely related to the aging degree of raw starch, and the aging degree is closely related to the drying method of instant food. At present, the main drying method of instant food is still frying drying. The drying rate of this method is fast, the aging degree of starch is small, and the quality of the finished product is good. However, there are some shortcomings such as high oil content, more loss of nutrients and short shelf life in the finished product, which can not meet the needs of people for green, environmental, healthy and nutritious instant food.

Therefore, using new drying methods to dry instant food is the focus of research. At present, the most widely used drying methods are hot air drying, microwave drying and hot air-microwave combined drying. However, people focus on the study of drying technology, while few studies have been reported on the effects of drying methods on the aging characteristics of instant food. Zhao Siming studied the aging mechanism and model of starch in the drying process of instant rice. The results showed that the aging of starch in the drying process could be explained by "two regions" and fractional separation model.

Therefore, the effects of hot air drying, hot air-microwave constant power drying and hot air-microwave variable power drying on the aging characteristics of instant rubber powder were studied in this paper, in order to provide theoretical basis and technical reference for the processing of instant rubber powder, which is of great practical significance for the development of health-care instant rubber, and also can improve the comprehensive utilization rate of acorn. At the same time, it promotes the development of local economy.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply