- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of different combinations of freeze drying methods on the quality of peach chips

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of different combinations of freeze drying methods on the quality of peach chips

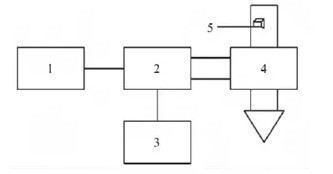

2019-01-10 14:45:36Abstract in order to study the effect of different combination of microwave drying equipment for peach chips quality, by vacuum freeze drying method for foundation and control, and with the hot air and microwave puffing, 3 kinds of methods for analysis and quality test dry combination experiment.

Key words: microwave drying of honey peach;Chips; Freeze drying; Combination drying

Peach belongs to Rosaceae, Prunus, native China, has a long history. Tender, juicy peach fragrant taste and sweet taste, rich nutrition, and has a clear skin, stomach, lungs, phlegm and other health effects, known as the "Queen of fruit" reputation, welcomed by the market.

Our peach mainly fresh food, but peach is the climacteric fruit ripening during high water, hot weather, postharvest storability, short shelf life, perishable, and low temperature and prone to damage, it is difficult to storage.

The fresh peach drying made of peach chips, is rich in peach processing product category, realize the peach deep processing of raw materials is an effective way to increase.

A lot of fruit and vegetable processing and drying methods currently used, mainly in hot air drying, vacuum drying, vacuum drying, microwave drying, explosion puffing drying, heat pump drying, vacuum freeze drying technology which can preserve the fresh materials, color, flavor and taste, shape and nutrition, is the production of high-quality, internationally recognized high value-added processing method of dehydrated foods But, there is a long drying time, high energy consumption, high cost products.

In recent years, some scholars will freeze drying and hot air drying, microwave and other means of combination, bamboo shoots, apples, carrots, Taihu whitebait, marine and other fruits and vegetables and aquatic products to carry out joint material on drying characteristics and product quality, show that the reasonable combination of freeze drying and other drying methods, can reduce and avoid the disadvantages of single use freeze drying products, can In order to shorten the drying time, reduce energy consumption and obtain the appropriate drying quality.

Now see the reports about peach processing and drying, drying methods involved are mainly the pressure difference puffing, far infrared drying, microwave drying, hot air drying, freeze drying and other drying methods and karyotype of peach varieties as raw materials by vacuum freeze drying method, and hot air, microwave and other 3 kinds of air puffing method of combined drying processing, study Effect of different combination of freeze drying method for peach crisp color, shrinkage, hygroscopicity, texture and microstructure, in order to provide technical basis for the production of dry peach chips.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply