- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Research progress on microwave drying technology of Litchi

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Research progress on microwave drying technology of Litchi

2019-01-11 14:15:39Absrtact: Litchi is not only delicious, but also of high edible, medicinal and economic value. However, because the storage time of fresh litchi is very short, it is easy to deteriorate, and the storage conditions are also very high.

If lychee is dehydrated and dried into dried litchi stem, not only the flavor and nutrients of fresh litchi can be maintained, but also the storage time of litchi can be prolonged to a great extent, and the added value of litchi can be increased. By summarizing the advanced drying technologies of litchi (heat pump drying, microwave drying equipment, vacuum freeze drying, hot air-heat pump combined drying), the application prospect of these advanced drying technologies was prospected.

Key words: litchi microwave drying; combined drying

Litchi, originating in southern China, is an evergreen tree of Sarcandinaceae. At present, litchi is planted all over the world. The planting range of Litchi in China is mainly concentrated in Guangdong and Fujian. Fresh litchi fruit is not only sweet and delicious, but also rich in a large number of nutrients needed by the human body. It can be used as a nutrient to meet people's needs.

In addition to rich nutrients, litchi also has some functions such as reducing blood lipid, detoxifying swelling, hemostasis and pain relief. Storage of fresh litchi is very difficult, because the fruit is prone to browning and decay, which greatly reduces the utilization of fresh litchi, and drying litchi first can make the use of litchi more widely.

The commonly used drying methods of litchi are traditional hot air drying and sun drying. These traditional drying methods have the disadvantages of poor quality, long drying time and high drying cost. In the drying process, too high drying temperature and too long drying time will also cause serious browning of the peel, which will reduce the quality, and also lead to a large number of bacterial growth and reproduction.

In the process of litchi drying, besides achieving the most fundamental purpose of dehydration, attention should also be paid to the appearance and quality of litchi. Several advanced drying technologies of litchi were introduced, including heat pump drying, microwave vacuum drying, vacuum freeze drying and hot air-heat pump combined drying.

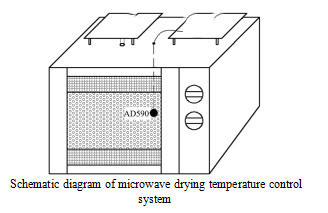

When drying litchi by microwave, in the early stage of drying, litchi has high moisture content and fast drying speed, which will form a relatively strong vapor pressure inside the litchi, which will lead to the cracking of the shell. Therefore, intermittent drying method is recommended to ensure the integrity and quality of litchi when drying by microwave.

Zhang Junhui et al. studied the effects of microwave vacuum drying on antioxidant and hypoglycemic effects of different varieties of litchi polysaccharides. The results showed that microwave vacuum drying of Feizixiao litchi had better hypoglycemic effect on diabetic mice. For general physical and chemical indexes (appearance, color, porosity and ascorbic acid content), microwave vacuum drying was better than hot air drying, but for litchi. The antioxidant activity of crude polysaccharides is not as good as that of hot air drying. The antioxidant activity of polysaccharides is affected by their molecular weight distribution and polyphenol content. In the process of litchi drying, the effects of drying methods on polysaccharides can be further studied.

In the existing research, the microwave vacuum drying test of litchi is usually designed and worked under laboratory conditions. In practical application, the adjustment and modification of specific parameters should be made according to specific conditions. How to make the experimental production and factory continuous production is also worthy of further study in the future.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply