- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of different drying methods on quality of wax gourd slices

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of different drying methods on quality of wax gourd slices

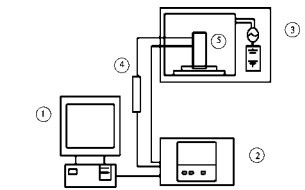

2019-01-14 13:13:55Absrtact: The effects of natural drying, ordinary hot air drying and microwave drying equipment on the quality of wax gourd were studied. The methods of long-term storage of wax gourd were explored by measuring the rehydration, vitamin C and acidity of wax gourd slices. The results show that the microwave drying method is the best in the above quality parameters.

Key words: Winter melon slices microwave drying; drying method; natural drying; hot air drying; microwave drying

Winter gourd, also known as cucumber, pillow gourd and cantaloupe, is a cucurbitaceous plant, which is resistant to storage and transportation, and is a good raw material for modern agricultural products processing. Wax gourd is rich in nutrition, with the functions of clearing heat and detoxification, dispelling dampness and heat, preventing and curing hypertension, losing weight and beautifying, etc. It also has a wide range of applications in the field of medicine. For a long time, wax gourd has been regarded as a good vegetable with both medicine and food at a low price and is favored by consumers.

Because the water content of wax gourd is very high (fresh sample moisture content is 95%-97%), especially in summer, it is easy to rot and deteriorate, which will cause losses to production. If it is dehydrated and dried, and the water content is reduced, it will last at room temperature, and it is also easy to carry and transport.

In this paper, the effects of different drying methods on the quality of wax gourd were studied by measuring the rehydration, vitamin C and acidity of wax gourd slices, so as to provide theoretical basis for further research on the drying technology of wax gourd.

The rehydration rate is microwave drying > natural drying > hot air drying. The higher the rehydration rate, the better the rehydration effect. Therefore, the rehydration rate of wax gourd slices dried by microwave is the highest. The reason is that microwave heating is heated from the inside of the substance and has the ability of automatic balance. It can avoid the surface hardening and other phenomena easily caused by conventional heating process. The heating effect is relatively uniform. Therefore, the structural characteristics of wax gourd slices during microwave heating process are well preserved and the rehydration rate is obviously higher than that of hot air drying and natural drying High dryness.

The order of drying ratio is microwave drying > hot air drying > Natural drying. Drying ratio is the ratio of pre-drying quality to post-drying quality, which reflects the drying degree of winter melon slices. The larger the drying ratio, the better the drying degree. Therefore, microwave drying is the best, natural drying consumes the most time and the effect is the worst.

Different drying methods have different effects on the quality of wax gourd slices. The results show that microwave drying not only has great advantages in drying ratio and rehydration rate, but also has the smallest impact on the retention of vitamin C, total acidity and density, which can better guarantee the quality of the products and maximize the nutritional value of wax gourd. Therefore, microwave drying can be used as a suitable drying method for wax gourd slices.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply