- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave-Electromagnetic Combined Drying of Peony Flowers

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave-Electromagnetic Combined Drying of Peony Flowers

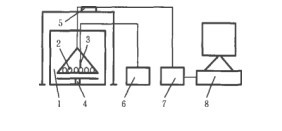

2019-01-15 15:39:13Absrtact: Microwave drying test-bed and electromagnetic heating drying test-bed, which can accurately measure output and reflection power, were used to study the microwave-electromagnetic combined drying process characteristics of peony. MatLab was used to fit the results of microwave and electromagnetic drying, and the best combination point of theory was found, which was verified by experiments.

The results showed that the optimum technology of microwave-electromagnetic combined drying of peony flowers was as follows: firstly, the moisture content of dry base of fresh peony petals was reduced to 99% by microwave drying equipment (power density was 5.97 W/g); then, the petals were dried to constant weight by electromagnetic drying (temperature was 60 C).

The dry base moisture content of fresh peony petals can be reduced from 313% to 4% within 30 minutes, which meets the storage conditions. Compared with hot air drying and freeze-drying, the time required for microwave-electromagnetic combined drying process is reduced by more than 85%, and the product phase can be maintained well.

Key words: microwave drying of peony flowers; microwave-electromagnetic combined drying; drying technology

Paeonia suffruticosa belongs to Paeonia suffruticosa group of Paeonia suffruticosa. It has high ornamental value and cultivation value. It is an important food and medicinal material at present, and has been paid more and more attention. In recent years, researchers at home and abroad have done a lot of analysis on the nutritional and health components of Peony Flowers, and found that Peony Flowers contain a variety of beneficial ingredients for human body, which have high nutritional value and health function.

However, peony flowers have short flowering period, high water content of petals, and are liable to corruption and deterioration. Tens of millions of peony flowers are wasted every year. Drying technology can not only prolong the preservation period of petals, but also facilitate the transportation of petals, meet the needs of a wider range, so as to give full play to the resource advantages of peony planting areas.

Existing peony flower drying technologies include hot air drying, freeze drying and microwave drying. Hot air drying equipment covers a large area, dries for a long time, pollutes seriously, and heating temperature is difficult to precisely control; freeze drying consumes a long time, consumes a large amount of energy and requires high technology, which not only restricts its own development, but also raises the drying cost, which is not conducive to market competition; microwave drying has the advantages of easy automatic control and shutdown at any time, and is suitable for seasonal agricultural products. In addition, microwave has bactericidal function and has great advantages in storage. With the wide application of microwave drying technology, more and more combined drying technology and biological production technology are combined with it.

Microwave vacuum drying combines microwave drying technology with vacuum drying technology, which has fast drying speed and high production efficiency. It is especially suitable for heat sensitive and highly viscous materials. The disadvantages of microwave vacuum drying are small size, expensive equipment and high process requirements.

Microwave vacuum freeze-drying combines microwave drying technology with vacuum freeze-drying technology, avoiding the problems of long processing time and high energy consumption of vacuum freeze-drying, and taking into account the sterilization function of microwave, it has outstanding advantages. The disadvantages are complex drying process, uneven heating, large echo, and glow discharge phenomenon, which limits its development.

Microwave-electromagnetic heating combined drying not only has fast drying speed, but also can control the upper temperature limit. Compared with microwave vacuum drying and microwave vacuum freeze drying, its equipment is cheap and easy to operate. In addition, the research on electromagnetic drying is less at present. The drying objects are mostly industrial products such as paper and molybdenum concentrate powder, and few agricultural products are involved. Therefore, the purpose of this paper is to make a beneficial attempt in microwave-electromagnetic heating drying of agricultural products.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply