- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effects of Different Drying Methods on Volatile Flavor Components of Silkworm Pupae

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effects of Different Drying Methods on Volatile Flavor Components of Silkworm Pupae

2019-01-16 13:48:56

ABSTRACT: In order to study the effect of different drying methods on volatile flavor compounds in silkworm pupae, solid phase microextraction and gas chromatography-mass spectrometry were used to analyze and compare the volatile components in fresh silkworm pupae by microwave drying equipment, vacuum microwave, hot air combined with vacuum microwave and vacuum freeze drying respectively, and to explore the different drying methods for drying silkworm pupae. The influence of volatile components in the product.

The results showed that 118 flavor compounds were detected in silkworm chrysalis and dry samples of silkworm chrysalis. The effects of drying methods on volatile flavor components such as alcohols, aldehydes, hydrocarbons and aromatics in silkworm chrysalis were obvious.

Among them, the main volatile components of hot air drying and vacuum microwave drying are hydrocarbons, and the main volatile components of vacuum freeze drying are aromatic substances. The content of aldehydes and ketones in the pupae of silkworm dried by hot air combined with vacuum microwave drying is higher than that of other drying methods, which can promote the effective formation of pupae flavor substances.

Key words: microwave drying of silkworm chrysalis; drying method; volatile flavor; extraction; gas chromatography-mass spectrometry

Silkworm pupa is the pupa of silkworm moth, which is the main by-product of silk reeling industry. It is rich in protein, fat and all essential amino acids for human body. The content of unsaturated fatty acids in silkworm pupa oil can reach 66.8%, which is mainly composed of alpha-linolenic acid and linoleic acid. It is a good medicine for treating hypertension, arteriosclerosis, diabetes and other diseases.

However, due to the special taste of silkworm chrysalis, it is limited in the field of food and medicine applications, so most of them are dried into animal feed, the economic value of resource utilization is very low. The analysis of volatile flavor components of silkworm pupa is helpful to improve the flavor of silkworm pupa in the process of processing and utilization of silkworm pupa resources, and to promote the development of high value-added silkworm pupa food and medicine.

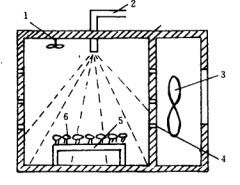

As an important way of food processing, drying reduces the moisture content of food to a certain extent, prolongs the shelf life and obtains dried food products. There are many drying methods, including hot air, microwave, vacuum microwave, freeze-drying and combined drying. Different drying methods have their own advantages, so appropriate drying methods should be adopted according to material characteristics to reduce energy consumption and improve product quality.

Therefore, the volatile flavor components of silkworm pupae were analyzed by solid-phase microextraction (SPME). The volatile flavor components of silkworm pupae were separated and identified by gas chromatography-mass spectrometry (GC-MS). The effects of hot air, vacuum microwave, hot air combined with vacuum microwave and freezing on the volatile flavor components of silkworm pupae were discussed. It lays a theoretical foundation for improving the flavor of silkworm pupa products.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply