- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on the Effect of Different Drying Technologies on Flower Quality of Camellia chrysantha

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on the Effect of Different Drying Technologies on Flower Quality of Camellia chrysantha

2019-01-16 14:11:55ABSTRACT: [Objective] To obtain the processing technology and technological parameters of high quality dried flower of Camellia chrysantha.

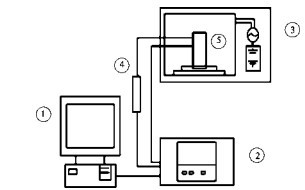

[Method] Microwave, vacuum freezing and vacuum freezing combined with hot air were used to dry Camellia chrysantha flowers. The appearance quality of the dried products was compared with that after brewing.

[Result] Microwave drying equipment was the best to maintain the appearance quality, followed by vacuum freezing-hot air combined drying. The product shape of microwave drying process was wrinkled with color change, and the effect was the worst. According to the evaluation method of tea, the best quality is vacuum freezing-hot air combined drying, followed by microwave drying, and vacuum freezing drying has the worst effect.

[Conclusion] High-quality dried flower products of Camellia japonica can be obtained by vacuum freezing-hot air drying process.

Key words: microwave drying of Camellia chrysantha; flowers; quality

Camellia chrysantha belongs to Camellia family and Camellia genus, and it belongs to the same family and genus as Camellia sinensis. In 1933, it was first discovered in Fangcheng, Guangxi, China. When it was rediscovered in Yongning, Guangxi in the 1960s, it stirred up horticultural circles at home and abroad. Since then, extensive research has been carried out on Camellia japonica. In 1965, it was named "Camellia japonica" by Dr. Hu Xiansu, a famous expert in plant taxonomy in China.

The origin of golden flower tea is mainly distributed in the South and southwest of Guangxi. It is a unique resource in Guangxi. It not only has certain nutritional value and medicinal value, but also has great ornamental value. It has golden petals and pistils, waxy golden yellow, crystal clear, bright and beautiful, giving a beautiful feeling.

Because of its rare and precious golden flowers, Camellia chrysantha is known as "Queen of the Tea Nationality" and "Giant Panda" in the botanical world. It has been listed as the first-class protected plant in the world. However, Camellia chrysantha has thick flowers with water content of 80%-85%. It can not be stored and transported easily. It must be dehydrated to less than 7% before it can be stored for a long time.

Microwave drying is widely used in the existing dehydration technology of Camellia chrysantha, which solves the problem of rapid drying. However, after drying, flowers shrink in shape, accompanied by browning in color, and lose the beauty of flowers. Starting from 2010, the shortcomings of discoloration and shrinkage of Camellia chrysantha flowers after drying were studied. The freeze-vacuum drying and freeze-vacuum-hot air combined drying experiments were carried out to eliminate oxidation reaction, water sublimation and ensure color and shape, and the process parameters were continuously optimized.

[Key issues to be solved by hot air] After drying, the color of flowers remains basically unchanged, the shape does not shrink, and the whole fragrance is pleasant.

[Significance of the study] Through the research of innovative technology, the dried flowers can keep their color and shape, retain the aesthetic feeling before drying to the greatest extent, and at the same time improve their inherent quality, so that the commerciality and selling point of Jinhua tea can be greatly improved, which provides technical support for strengthening and expanding the characteristic industry of Guangxi.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply