- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of Different Drying Methods on Antioxidant Activity of Radix Astragali in Vitro

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of Different Drying Methods on Antioxidant Activity of Radix Astragali in Vitro

2019-01-17 15:32:20[abstract] Objective: To compare the effects of different drying methods on the antioxidant activity of Radix Astragali in vitro, so as to optimize Radix Astragali.

The establishment of drying process provides experimental basis.

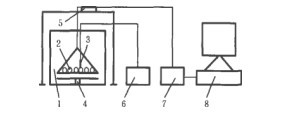

Methods: Radix Astragali was dried by sun drying, shade drying, electrothermal blast drying, microwave drying equipment, vacuum freeze drying and vacuum drying respectively. The effects of different drying methods on antioxidant capacity of Radix Astragali in vitro were investigated by DPPH in vitro reaction system.

RESULTS: Different decoctions had scavenging effects on DPPH free radicals, but their scavenging abilities were different. Microwave drying is the strongest, followed by drying, sun drying, vacuum drying, shade drying, vacuum freeze drying, the weakest removal capacity.

CONCLUSION: Microwave drying and electric blast drying are simple, rapid and efficient, and can replace the traditional drying method for drying Radix Astragali.

[keywords] Radix Astragali microwave drying; drying method; antioxidant activity in vitro

Astragalus membranaceus is the dry root of Astragalus membranaceus. Liupanshan Mountain in Gansu Province and the mountainous areas in the south,4

Northwest Sichuan and other places. It has the functions of Invigorating Qi and promoting yang, fixing the surface and relieving sweat, diuresis and edema, nourishing body and blood, stagnation and obstruction, detoxification and purulence, sores and muscles.

It is often used for deficiency of Qi and fatigue, lack of food and stool, depression of mid-qi, prolonged diarrhea and anal collapse, bleeding and bleeding, surface deficiency and self-sweating, deficiency of Qi and edema, internal heat and thirst, deficiency of blood and yellow, hemiplegia, paralysis and numbness, carbuncle is difficult to collapse, and prolonged collapse and astringency.

Modern pharmacological studies have shown that Astragalus membranaceus has immune regulation, anti-tumor, anti-oxidation, anti-cancer and other functions. In recent years, the antioxidant effect of Radix Astragali has been paid more and more attention by researchers. The effects of different drying methods on the antioxidant activity of Radix Astragali in vitro were compared by DPPH in this paper, and the experimental basis was provided for the establishment of the optimal drying process of Radix Astragali.

Put the fresh Radix Astragali medicinal materials in the material tray and in the sun, keep ventilation and air permeability, and record the temperature and humidity at that time. In the drying process, it is necessary to turn over the sun from time to time to make it dry quickly. In the drying process, attention should be paid to weighing the quality of Radix Astragali. The quality difference between before and after drying should not exceed 0.01 g, and the drying end.

Put the Astragalus in the material tray and place it in the cool and ventilated place. Record the temperature and humidity of the drying environment. Turn over from time to time during the drying process to avoid mildew and moth. Attention should be paid to weighing the quality of Astragalus in the drying process. The quality difference before and after drying should not exceed 0.01 g, and the drying end.

Put the medicinal materials in microwave oven and dry them at low temperature. Weigh the quality of Radix Astragali every 1 minute. When the quality difference between before and after does not exceed 0.01 g, the drying is over.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply