- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying methods on aging characteristics of instant rice flour

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying methods on aging characteristics of instant rice flour

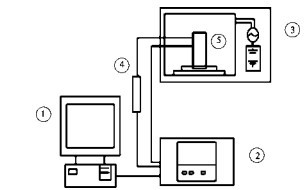

2019-01-21 14:19:43Absrtact Rapid Visco Analyser (RVA), X-ray diffraction and FTIR were used to study the effects of different drying methods (freeze-drying, hot air drying, microwave drying equipment) on the aging characteristics of instant rice flour.

The results showed that the absorbance ratio, crystallinity, gelatinization temperature and retrogradation value of instant rice flour obtained by hot air drying were the largest at infrared 1 047/1 022 cm-1, indicating that the aging degree of instant rice flour obtained by freeze-drying was the smallest, followed by microwave drying.

The rehydration rate and rehydration time of instant rice flour obtained by different drying methods were studied. The rehydration rate of freeze-drying was the best and that of hot-air drying was the worst. The rehydration performance of instant rice flour may be related to its aging degree in drying process.

Key words: microwave drying instant rice flour; aging; rehydration

Instant rice flour is a kind of fast developing instant food in recent years. The deterioration of instant rice flour quality is related to the aging of starch, such as slow rehydration speed and poor viscoelasticity. There are many factors affecting starch aging, including starch source, gene type, gelatinization conditions, cooling rate, concentration, storage temperature, moisture content, pH and other non-starch components (such as fat, salt, sugar).

The aging of convenience food is mainly produced in the drying process. Some studies have shown that drying process has an important influence on the transformation of starch from amorphous to crystalline zone after gelatinization, and this aging phenomenon is persistent in the drying of starch food. Recrystallization of gelatinized starch also hardens the quality of products. Zhao Siming and other studies on instant rice also show that the hardness of instant rice is closely related to the aging of starch during drying.

Drying is one of the important processes in the production of instant rice flour. The effect of drying process on the aging of instant rice flour is rarely reported. Therefore, the effects of hot air drying, microwave drying and freeze drying on the aging of instant rice flour were compared in order to provide theoretical guidance for the industrial production of instant rice flour.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply