- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Optimization of Microwave and Hot Air Combined Drying Technology for Sugar and Ginger Tablets

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Optimization of Microwave and Hot Air Combined Drying Technology for Sugar and Ginger Tablets

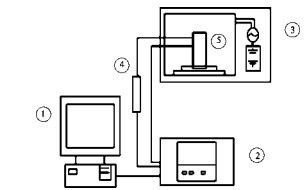

2019-01-23 13:16:21ABSTRACT: In order to explore the rapid drying method of Sugar and Ginger Tablets, the drying technology of Sugar and Ginger Tablets by microwave and hot air was studied. Firstly, the effects of microwave drying equipment, moisture content at conversion point and hot air temperature on the content of gingerol in Sugar and Ginger Tablets were investigated.

Then three factors and three levels of response surface were used to design and optimize the drying conditions of microwave combined with hot air, and the corresponding regression equation was established. The results show that the optimum combined drying process conditions are: microwave power 239 W in the early stage, moisture content 65% at the conversion point, and hot air temperature 61 C in the later stage. Under these conditions, the content of gingerol in Tangjiang tablets was (0.73 (+0.025)%. The relative error between the actual measured value and the theoretical predicted value was - 2.67%. The two values basically coincided.

Compared with hot air drying and microwave drying alone, the content of gingerol in sugar and ginger tablets dried by microwave and hot air was increased by 30% and 14% respectively. It provides scientific reference for further processing research and development of ginger products.

Key words: microwave drying of sugar and ginger tablets; hot air drying; combined drying; response surface methodology

Ginger is the rhizome of perennial herbs of Ginger family. It belongs to the homology of Chinese medicine and food. It is also one of the spices that people eat daily. Its chemical composition is complex. There are about 100 kinds of chemical constituents, which are mainly divided into three categories: volatile oil, gingerol and diphenylheptane. Among them, gingerol is the main flavoring substance with the special pungent taste of ginger, and it is also one of the main functional active ingredients of ginger.

The chemical properties of gingerol are unstable, and it is vulnerable to acid, alkali and temperature. Ginger has been widely concerned by consumers at home and abroad in recent years because of its edible and medicinal value, such as dispelling wind and dispelling cold, stopping vomiting, antioxidant, lowering cholesterol, lowering blood sugar, anti-cancer, detoxification and sterilization, and the variety of ginger products is also increasing. Common ginger products such as ginger tea, ginger milk curd, ginger vinegar beverage, sugar and ginger tablets, ginger powder solid granules, etc. Sugar and ginger tablets are popular among consumers because of their unique flavor, vomiting prevention and easy to carry.

Dehydration and drying is one of the important links in the processing of ginger products, which affects the processing quality and drying efficiency of sugar and ginger slices. Traditional sugar and ginger tablets are mainly sun-dried and hot-air-dried. They have the advantages of simple operation and less investment in equipment, but they also have the disadvantages of low drying efficiency, long drying time and poor quality.

In recent years, microwave drying has attracted wide attention. Compared with hot air drying, microwave drying has the advantages of fast drying speed, energy saving, pollution-free and easy operation. In order to shorten drying time and improve product quality, the combination of microwave and hot air drying has become one of the trends of joint drying research at home and abroad.

The results showed that microwave drying combined with hot air drying could effectively shorten the drying time and improve the quality of Macadamia nuts. Fang Shuzheng et al. showed that compared with hot air drying, microwave combined with hot air drying could improve the quality of jujube products and reduce energy consumption by 55%.

Tang Xiaojun et al. used microwave and hot air to dry balsam pear. The results showed that the drying time could be effectively shortened and the quality of dried balsam pear products could be improved. Deepak Kumar et al. used microwave-assisted hot air drying to dry okra, which showed that the quality of combined drying was better than that of hot air drying products. Therefore, domestic and foreign research shows that microwave combined with hot air drying has the advantages of fast drying rate and high product quality.

At present, there are few reports on the combined drying of sugar and ginger tablets by microwave and hot air. Therefore, the technology of microwave combined with hot air drying for sweet ginger tablets was studied in this paper, in order to provide scientific reference for the production and development of ginger products, combining the advantages of the two drying methods.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply