- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying process on quality of low temperature sausage

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying process on quality of low temperature sausage

2019-01-24 10:27:49Absrtact: Low-temperature sausage was developed with pork and fish sauce as main raw materials. The drying conditions were optimized. The effects of hot air drying time, microwave drying equipment and microwave time on the quality of low temperature sausage were discussed.

The results showed that the shape, color, taste and taste of meat sausage increased with the prolongation of hot air drying time, while the difference of internal and external moisture content decreased. After microwave treatment, it is helpful to balance internal and external moisture content, improve color uniformity and sensory quality. However, too long time will lead to poor taste, high hardness and color decline of meat sausage. The best drying technology of low-temperature sausage is to dry it for 14 hours in a hot air drying box at 55 C, and then dry it in a 250W microwave oven for 90 seconds.

Key words: microwave drying of meat sausage,Hot air drying, moisture content

China is the world's major freshwater fish farming country, surimi products are one of the main aquatic products, in the process of processing will produce a large number of by-products, such as fish head, fish bones and so on. Fish bone is rich in protein, calcium and other nutrients, and has a high absorption and utilization rate. It is a good natural protein and calcium source.

At present, these by-products are mainly used in feed processing with low added value or discarded directly, resulting in huge waste. Therefore, processing fish bones or three removed fish bodies into fish sauce can not only improve the nutritional value of pork sausage, but also increase its added value.

Low temperature meat products are the main trend of meat products development in China in the future. The heating temperature of low temperature meat products is generally in the range of pasteurization temperature. Compared with high temperature meat products, it has better flavor and nutritional value, but it also has some common defects such as poor texture, poor taste, effluent and so on.

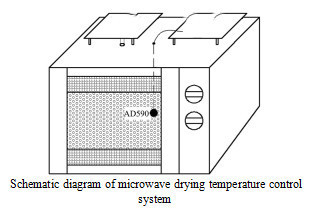

Baking is the main process affecting the quality of low-temperature sausage, which takes a lot of time. In order to shorten the processing time and ensure product quality, we tried to use hot air microwave drying method to dry sausage.

The results show that drying hot air to a certain moisture content before microwave drying can greatly shorten the drying time, reduce energy consumption, and have better sensory quality and rehydration. At present, hot air-microwave combined drying technology is mainly used in fruit and vegetable production, but there are few reports about meat products.

Fish paste was prepared from carp by micronization. A low-temperature sausage was made by mixing fish sauce with pork. The effects of hot air drying time, microwave time and microwave power on sausage quality were studied, and the optimum technological conditions were obtained.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply