- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Characteristics and quality evaluation of hot air-microwave combined drying of pumpkin slices

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Characteristics and quality evaluation of hot air-microwave combined drying of pumpkin slices

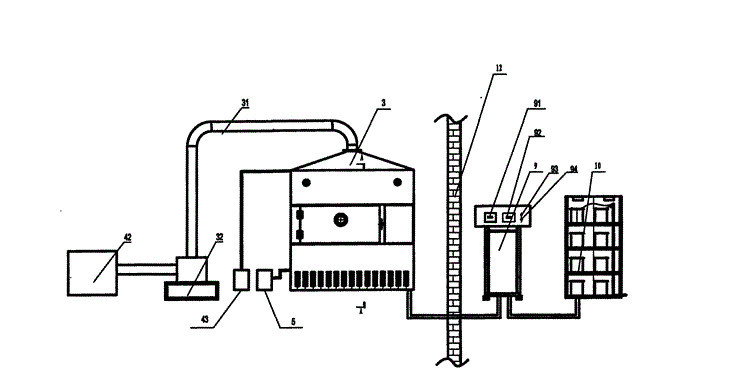

2019-01-25 10:34:25In order to explore the efficient drying method of pumpkin, the characteristics of hot air-microwave combined drying of pumpkin slices were studied, the applicability of six mathematical models were compared, and the microwave drying equipment, rehydration ratio, drying time and energy consumption of pumpkin slices were compared and analyzed.

The results showed that the drying rate curve of pumpkin slices in the early stage of hot-air-microwave combined drying was consistent with that in the corresponding stage of single hot-air drying, and the later stage was divided into increasing and decreasing stages. In hot-air-microwave combined drying, the Midilli-Kucuk model was suitable for describing the early stage of hot-air drying, while the Modified Page model was suitable for describing the later stage of microwave drying; the browning of pumpkin slices obtained by combined drying was less serious than The retention of carotenoids was better than that of microwave drying.

The rehydration ratio of combined drying was lower than that of hot air drying and higher than that of microwave drying. Compared with hot air drying, the drying time and energy consumption of hot air-microwave combined drying method are shorter and lower. Compared with hot air drying, the drying time and energy consumption of hot air-microwave combined drying method are reduced by 45% and 48%. The hot air-microwave combined drying method has the characteristics of good quality and low energy consumption, and is more suitable for the drying of pumpkin slices.

Key words: pumpkin slices microwave drying; hot air drying; combined drying; drying model; quality evaluation

Pumpkins are Cucurbitaceae pumpkins, and their fruits and seeds are edible. Pumpkin contains carotene, vitamin B, vitamin C, calcium, phosphorus and other nutrients needed by the human body, but also contains a large number of pumpkin seed alkaloids, alkaloids, cucurbitacin and pectin and other physiological active substances. Fresh pumpkin has high moisture content and can not endure storage. Even under cold storage conditions, fresh pumpkin can easily cause microbial growth and decay. Drying is the most widely used storage method of pumpkin at present.

With the development of the times and the progress of science and technology, the comprehensive application of various drying methods, namely combined drying, has become a trend of modern drying technology. Combined drying refers to a composite drying technology which combines two or more drying methods according to the characteristics of materials, complements each other, and carries out in stages or at the same time.

In recent years, the research on combined drying has gradually increased, and scholars have put forward some better methods of combined drying. Because of the fast drying speed, high product quality, simple operation and less investment in equipment, microwave drying as a heat source and hot air drying has become a hot spot of researchers'attention. Liu Qingmei et al. studied the combined drying technology of hot air and microwave for Fritillaria fritillaris. The results showed that the drying time of this technology was 65% shorter than that of hot air drying, and the quality of Fritillaria fritillaris was better than that of single drying method.

Xu Yanyang et al. found that compared with single hot air drying and microwave drying, the gingerol content of sugar and ginger tablets dried by microwave combined with hot air increased by 30% and 14%, respectively. The above research shows that the combined drying technology of hot air and microwave has obvious advantages in improving drying rate, reducing energy consumption and improving product quality.

At present, single drying method is often used for pumpkin drying. Using pumpkin as raw material, the characteristics and mathematical model of hot air-microwave combined drying of pumpkin slices were studied. The color, rehydration ratio, drying time and energy consumption of pumpkin slices were analyzed, which provided theoretical basis for the development of new technology and equipment of hot air-microwave combined drying of pumpkin slices.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply