- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Kinetic Fitting and Quality Change Analysis of Strawberry Infrared Drying

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Kinetic Fitting and Quality Change Analysis of Strawberry Infrared Drying

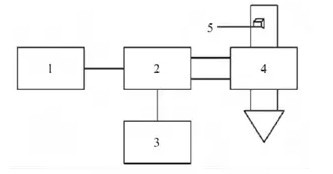

2019-01-25 13:10:54In order to improve the drying efficiency and product quality of strawberry, mid-short wave infrared drying technology was applied to strawberry drying, and the drying characteristics and quality changes were studied under different microwave drying equipment (60, 70, 80 and 90 C) and different drying power (675, 1 125, 1 575 and 2 025 W).

The mid-short wave infrared drying of strawberry belongs to the process of deceleration drying, which has a fast drying speed, and the drying temperature has a significant influence on the drying power. The effective diffusion coefficient of water is 0.607 *10-9~2.126 *10-9 m2/s, and the activation energy E of mid-short wave infrared drying of strawberry is 39.54 kJ/mol. The model fitting shows that the best model for describing the mid-short wave infrared drying of strawberry is Page. Model.

The color of strawberry products was better at 70 C, 1 125 W drying power and 190 min drying time. The rehydration ratio was 3.59, the hardness was 3 128.01 N, the content of VC was 259.93 mg/100 g, the content of cypermethrin-3-glucoside was 0.23 mg/100 g, the content of geranidin-3-glucoside was 2.79 mg/100 g, and the comprehensive quality of strawberry was better.

Key words: strawberry microwave drying; mid-short wave infrared drying; model fitting; cyanidin-3-glucoside; geranin-3-glucoside

Hot air drying, microwave drying and vacuum freeze-drying are commonly used in the drying of fruits and vegetables. However, these drying methods will produce some disadvantages, such as hot air drying resulting in large color change, large shrinkage and low rehydration.

Microwave drying can effectively accelerate the drying rate, but the content of bioactive substances and rehydration of products are reduced, and due to its special heating mechanism, the samples are not uniformly heated. In the vacuum freeze-drying process of strawberry, although the color quality is good, the energy consumption is high.

Mid-short wave infrared drying is a new processing technology in fruit and vegetable drying in recent years. It can not only greatly improve the drying rate and shelf life of fruit and vegetable, but also improve the quality and economic value of fruit and vegetable.

Compared with the traditional drying method, it has great advantages and has been successfully applied to carrot, mushroom, onion and blueberry and other fruit and vegetable raw materials. The effects of drying temperature and power on the drying characteristics, color, hardness and VC of strawberry were studied.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply