- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave Drying Characteristics of Lycium barbarum and Its Effect on Quality

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave Drying Characteristics of Lycium barbarum and Its Effect on Quality

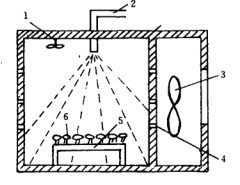

2019-01-25 14:53:30Absrtact: In order to shorten drying time and save drying cost of Lycium barbarum, the microwave drying characteristics of Lycium barbarum and its effect on product quality after drying were studied by using microwave test device and selecting unused drying power and material laying thickness.

The results showed that the drying period of Lycium barbarum could be greatly shortened by microwave drying equipment during the slow drying stage. The drying time of microwave combined drying was about 65 hours shorter than that of natural drying, accounting for 72% of the drying period of natural drying.

Drying power and material layer thickness are important factors affecting microwave drying time. The larger the microwave power is, the smaller the material layer thickness is, the shorter the drying time is. Different microwave drying parameters have different effects on the quality of dried products. Microwave power is 1 kW. When the material layer thickness is 2 cm, the preservation rate and sensory quality of dried polysaccharides are the best.

Key words: microwave drying Lycium barbarum; drying characteristics; quality

Modern pharmacological studies have confirmed that Lycium barbarum can regulate the immune function of the body, effectively inhibit the growth of tumors and cell mutations, and has the functions of delaying aging, anti-fatty liver, regulating blood sugar and blood lipid, etc. Fresh fruits of Lycium barbarum have high moisture content and rich polysaccharides. If they cannot be dried in time, they will become spoiled and mildewed, which seriously affects the yield and quality of Lycium barbarum and greatly reduces the economic benefits.

Traditional hot air drying and natural air drying have the characteristics of long drying time, high energy consumption and poor drying quality. Microwave drying is different from hot air and other drying methods. Because of its unique heating characteristics, fast drying speed, high quality after drying and high heat utilization rate, microwave drying has attracted more and more attention in the fields of medicine, food industry, chemical industry, tobacco, and agricultural products processing.

The research on microwave drying of grain and fruit and vegetable has been started in foreign countries more than ten years ago. In recent years, there are also studies on the application of microwave drying technology in grain seed drying, fruit and vegetable drying, deep processing of medicinal materials, and drying of aquatic products. Some of them have been successfully applied and achieved remarkable economic benefits.

However, there is no literature report on the microwave drying characteristics of Lycium barbarum. Therefore, the microwave drying experiment of Lycium barbarum was carried out in order to analyze the microwave drying characteristics of Lycium barbarum and its influence on the quality and energy consumption after drying, and further explore the application of microwave technology in Lycium barbarum drying.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply