- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Optimization of Microwave Drying Technology for Ginkgo biloba Fruit

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Optimization of Microwave Drying Technology for Ginkgo biloba Fruit

2019-01-26 09:36:14

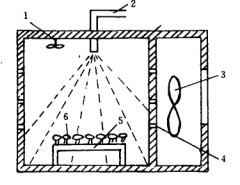

Absrtact: In order to explore the optimum technology of microwave drying equipment for Ginkgo biloba fruit, microwave power, heating time and intermittent time were selected as experimental factors, average drying energy consumption, mass drying rate and sensory quality score after drying were taken as evaluation indexes, quadratic orthogonal regression test was used to optimize the microwave intermittent drying technology for Ginkgo biloba fruit, and quadratic regression was established by Backward analysis method. Mathematical model and response surface analysis of regression model.

The results show that the selected experimental factors have a significant influence on the drying process, and the order of strength is heating time > microwave power > intermittent time. There is interaction between the experimental factors.

The optimum drying parameters of Ginkgo biloba fruit were microwave power 4.5 W/g, heating 6.5 s and intermittent 80 s. Under these conditions, the drying rate was 0.157 kg/(h.kg), the average energy consumption was 65.54 kJ/g, and the sensory quality score was 8.5. The experimental results have certain reference value for improving drying equipment and microwave drying of Ginkgo biloba fruit.

Key words: microwave drying of Ginkgo biloba fruit; microwave intermittent drying; orthogonal regression; response surface analysis

Ginkgo seed core, also known as white fruit, contains rich protein, fat, sugar, crude fiber, and a small amount of VB1, VB, as well as potassium, iron, calcium, phosphorus and other minerals, eating Ginkgo fruit, not only can nourish the body, but also can prevent and cure many diseases, its economic value has been more and more recognized by people.

However, the germ of Ginkgo biloba has certain toxicity. Generally, it needs to be hulled, peeled and de-germinated. The cytotoxic components such as white fruit alcohol, white fruit phenol and white fruit acid can be eliminated by soaking and cooking in order to reduce the toxicity. Therefore, deep processing of Ginkgo biloba fruit should first be shelled, and fresh Ginkgo biloba fruit has high moisture content, which is not conducive to long-term storage and mechanical shelling. Therefore, drying of Ginkgo biloba fruit is very necessary.

The traditional drying method of Ginkgo biloba fruit is hot air and natural air drying. At present, previous studies have carried out hot air drying experiments on Ginkgo biloba fruit. The results show that the drying time is as long as 12-14 hours, and the energy consumption is high. The microwave intermittent drying technology has the advantages of fast, high efficiency and good drying quality. In recent years, it has been widely used in the production and processing of agricultural products.

In China, some researchers have optimized the microwave intermittent drying technology for longan, litchi, pepper, corn and other materials. In foreign countries, some researchers have studied the microwave drying technology for pumpkin, spinach and cabbage leaves respectively. The experimental results show that microwave intermittent drying of different agricultural products not only has high efficiency, low energy consumption, but also has good drying quality. The study on Microwave intermittent drying of Ginkgo biloba fruit has not been reported.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply