- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Effect of drying process on sensory quality of scented tea and toxicological evaluation

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Effect of drying process on sensory quality of scented tea and toxicological evaluation

2019-01-28 11:01:20Abstract: The effects of different drying processes on the sensory quality (shape, aroma, taste, color) of scented tea were compared. The acute toxicity and genotoxicity of the samples were studied. The results showed that microwave pretreatment could kill polyphenol oxidase and peroxidase of thrips.

From the morphological point of view, freeze-dried fragrant tea is the best; aroma at 420 W microwave drying is the best; taste is also the best freeze-dried. From the comprehensive score, the sensory quality of freeze-dried fragrant tea was the best, followed by microwave drying equipment, and the sensory scores of vacuum drying and hot air drying had little difference. The effects of drying methods on the color L*, A*, B* of tea soup were basically consistent with the sensory evaluation indexes. The results of acute toxicity and genotoxicity of thistle were negative.

Conclusion: Among several drying methods, the quality of freeze-dried fragrant tea is the best. Among other drying methods, the quality is relatively good under microwave 420W, vacuum 50 C and hot air 80 C.

Key words: microwave drying of silk flowers; drying process; sensory quality; toxicological evaluation

Loquat. It is a small evergreen fruit tree with medicinal value in subtropical zone. It has been planted in China for more than 2200 years. The production areas are mainly distributed in Zhejiang, Fujian, Anhui, Sichuan and other provinces and regions. The flower buds and inflorescences are warm, mild, fragrant and sweet. According to the Compendium of Materia Medica, the flower is thirsty, stuffy, vomiting, clearing away heat and moistening five Zang organs. It is reported that the flower contains flavonoids, polyphenols, triterpenoid saponins and other active ingredients, and has the functions of expectoration, cough relief and lung clearance. It has high medical and health care value.

Each inflorescence of thistle has 80 to 100 flowers. In the process of Alfalfa cultivation, in order to improve the quality and yield of fruit, fruit trees must be thinned, each plant should dredge 60% - 80% of the fresh buds. Falling, so that the fruit of the remaining flowers have more nutrition. Therefore, silk flower resources are rich. Alfalfa has become a research hotspot, but most of the research focuses on the extraction of flavonoids and triterpene acids from alfalfa. In the early stage, the authors analyzed the content of main active ingredients in different flowering stages and tissues, and the effect of different drying methods on the content of active ingredients.

At present, there are few studies on the effects of drying methods on the sensory quality of scented tea. Lu Yan's study compared the effects of drying, microwave and cooking on the sensory quality of fragrant flowers, but did not study the subsequent drying methods. The sensory quality of fragrant tea, such as solid shape, soup color, aroma and taste, was compared by using the sensory evaluation method of tea.

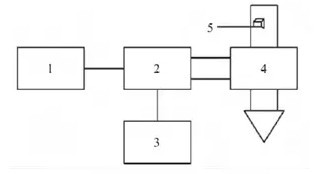

Polyphenol oxidase and peroxidase in plant materials can cause enzymatic browning during drying and affect sensory quality. Therefore, the enzyme will be inactivated before drying. The effects of microwave and hot steam on the activities of two enzymes in thistle were studied. In order to study the food safety of silk tea, the toxicological test of silk flower was also carried out in this experiment, which provided scientific basis for the processing and utilization of silk flower.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply