- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Study on Microwave Drying Process of Lotus Seeds

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Study on Microwave Drying Process of Lotus Seeds

2018-10-31 15:48:06

Take lotus seed 300 g, fixed wind speed 1.5 m / s, set the wind temperature 40,

50, 60, 70, 80 °C, hot air drying, study the effects of different air temperature on the drying process and product rehydration, determine the appropriate microwave drying equipment conditions.

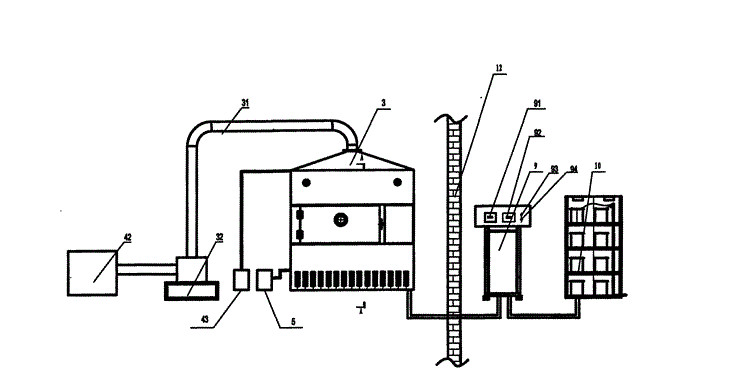

1.3.2 lotus seed microwave drying equipment the study

Take 300 g of lotus seeds, set the microwave power of 1, 2 kW under vacuum condition of 0.1 MPa, vacuum microwave drying, study the influence of different microwave power on the drying process and product rehydration, and determine the appropriate vacuum microwave drying process. condition.

1.3.3 Research on Vacuum Freeze-drying Process of Lotus Seeds

300 g of lotus seeds were taken and pre-frozen at -40 °C for 2 h in a vacuum freeze dryer. Under the conditions of vacuum of 60, 90 and 120 Pa, the freeze-drying conditions were set to the first stage -20 °C/12 h. The second stage was -10 °C / 12 h, and the post-drying stage was 30 °C for 10 h. The effects of different vacuum degrees on the freeze-drying process and product rehydration were studied, and the suitable vacuum freeze-drying process conditions were determined.

1.3.4 Research on the hot air-vacuum microwave drying process of lotus seeds

Take 300 g of lotus seeds, dry the lotus seeds with suitable hot air drying conditions to a moisture content of 20%, 30%, 40%, and wet at 6 °C for 6 h, then under a vacuum of 0.1 MPa. Vacuum microwave drying was carried out under the condition of microwave power of 1 kW. The effects of different pre-drying moisture content on the drying process and product rehydration were studied, and the suitable hot air-vacuum microwave drying process conditions were determined.

1.3.5 Study on the hot air-air puffing and drying process of lotus seeds

300 g of lotus seeds were taken, and the lotus seeds were dried to a moisture content of 20%, 30%, 40%, and dried at 4 °C for 6 h, and then air-expanded and dried (expansion pressure difference 0.124). MPa, puffing temperature 95 °C, evacuation drying temperature 70 °C, drying time 120 min), study the effect of different pre-drying moisture content on drying process and product rehydration, and determine the suitable hot air-air puffing drying process conditions.

Different drying methods have an effect on the color of lotus seed drying products. The order of total color difference of the five different drying methods is vacuum freeze-drying>hot air-air puffing drying>hot air drying>vacuum microwave drying>hot air-vacuum microwave drying. The total color difference between the vacuum microwave drying and the hot air-vacuum microwave drying is lower than that of the hot air drying product, that is, the products obtained by the two drying methods are darker than the hot air drying product, which may be due to the rapid heating of the microwave and the lotus seed. The internal heat is unevenly distributed, causing local scorching to deepen the color of the product.

The total color difference of the product obtained by hot air-air puffing drying is close to that of hot air drying products. The total color difference of the vacuum freeze-dried product is higher than that of the hot air drying product, that is, the color of the product is whiter than that of the hot air drying product. This may be due to the fact that the volume does not shrink during the drying process, and the product does not undergo high temperature and under a certain degree of vacuum, so that the product does not undergo significant browning.

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply