- Shandong Microwave Machinery Co.,Ltd.

- To be the Leader of microwave drying and edible oil refining equipments Manufacturer

Home> Company News> Microwave drying characteristics of corn and its effect on quality

- AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Factory AddressNo. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)+86 0531 85064681

- Phone(Nonworking Time)0086-15020017267

- Fax+ 86 0531 85064682

Microwave drying characteristics of corn and its effect on quality

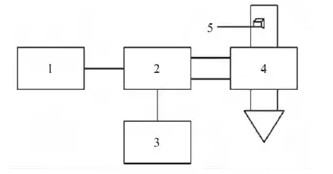

2018-10-17 14:41:13[Abstract] Aiming at the problems of hot air drying of maize, the effects of drying characteristics and drying conditions on the quality and energy consumption of maize after drying were studied by using a self-made microwave drying equipment test system with different drying power, heating time and matching technological process. The relationship between the potential mass power consumption, temperature, average water loss rate and the germination rate, crack rate and starch yield of maize was studied. The technological parameters and the optimum technological process of microwave drying maize were determined. The results showed that the microwave drying of maize was mainly in the stage of constant speed drying. The application of microwave technology could not only dry maize grain quickly and economically, but also maintain its seed value and improve its quality.

Introduction

Because of the weather, the moisture content of Maize during harvest is on the high side. If the maize can not be dried in time, it will become moldy and rotten, which seriously affects the yield and quality of maize. The traditional hot air drying method, when the material is heated first outside and then inside, the drying effect and drying quality are poor, especially the corn grain is large, the unit specific area is small, the grain cortex structure is tight and smooth, the moisture content is difficult to follow.

The grain is transferred from inside to outside. Especially under the action of high temperature medium, the moisture in the epidermis of maize grain evaporates sharply, and the moisture under the epidermis can not be transferred in time, resulting in increased pressure, epidermis cracking, starch gelatinization, starch yield decreased, and the quality of maize decreased significantly after drying. Microwave drying of corn is different from hot air and other drying methods, because of its unique heating characteristics.

Second stage Zhu Dequan et al. Characteristics of microwave drying of corn and its effect on quality 73

1 test materials and methods

1.1 test materials

Corn: "Ye Dan No. 19", made by Anhui Agriculture University.

Supply.

1.2 test and determination methods

Quality measurement: measured by TG725C single plate analytical balance.

The accuracy is + 0.01 g.

Temperature measurement: radiation T H1 400 thermometer, accuracy is

1 degrees centigrade.

Moisture determination: according to GB5497 - 85 method, 130 C timing drying method was carried out in 101 type electric constant temperature box.

Determination of germination rate: according to GB 5520 - 85 method, 1011.

The electric heating box is carried out in constant temperature box.

Determination of starch yield: determined by GB / T 5514 - 85 method.

Determination of crack rate: 100 corn grains were randomly selected from the Microwave Treated Corn grains, and the number of cracked grains was picked out, that is, the crack rate of corn (each sample was tested three times, the result was taken as the average).

L25 (5) orthogonal test was carried out with drying power A, temperature B and wind speed C as experimental factors and germination rate L, crack rate R and starch yield D as evaluation indexes (see Table 1).

Tab. 1 Factors and levels of orthogonal experiment

| 水平 | A / W· g- 1 | B /℃ | C /m· min- 1 |

| 1 | 0. 15 | 40 | 30 |

| 2 | 0. 20 | 50 | 45 |

| 3 | 0. 25 | 60 | 60 |

| 4 | 0. 30 | 70 | 75 |

| 5 | 0. 35 | 80 | 90 |

High efficiency food beverage factory stone paper production line

High efficiency food beverage factory stone paper production line Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line

Factory price Fully automatic Machine PP/PS Plastic Sheet Production Line used deformered bar rolling mill production line

used deformered bar rolling mill production line Manufacturing plant automatic factory puffed sticky rice cracker production line

Manufacturing plant automatic factory puffed sticky rice cracker production line Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply

Production Line Pp Ppr Plastic Pipe Making Machine 20-63mm Multi-layer Extrusion Production Line For Water Supply